PP Woven Flour Bag Making Machine

Description

Basic Info.

| Model NO. | QL-PC-4/750 |

| Customized | Customized |

| Condition | New |

| Weight | 1800kgs |

| Total Power | 2/2.7kw |

| Transport Package | Suitable to Export |

| Specification | QL-PC-4/750 |

| Trademark | Qunli/Wanqun |

| Origin | Zhejiang, China |

| HS Code | 8447120000 |

| Production Capacity | 500sets/Month |

Product Description

4-shuttle circular loom for PP woven bagProduct Application

This machine is mainly used for producing PP woven bags for cement, rice, fertilizer, chemical mateials, animal feed and sugar etc.

It uses material of polypropylene (pp) & high density polyethylene(HDPE) for producing PP woven bag.It was designed and researched on the base of original circular loom, it is the substitute product of present common circular loom .

It improves whole shuttle,raceway and cam .The best advantage is high production effciency and smooth weaving flatness .Our factory supplys the machine for testing.Because of reasonable desigh, high quality material, it's spare parts consumption is lower than normal circular loom,also the life of the runway can reach 10 years.

| SPECIFICATIONS FOR 4 SHUTTLE CIRCULAR LOOM | |

| Number of spindle | 4pcs |

| Lay-flat width(10-24warps/100mm) | 350-750mm |

| Max.warp | 768pcs |

| Rotaional speed of main body | 140-180r/min |

| Power of main motor | 1.5/2.2kw |

| Total power | 2/2.7 |

| Capacity | 1.4-1.8m/min |

| Installing dimensions | 8400x2200x2650mm |

| Weight | 1800kgs |

Main Features

1) With the scroll transmission by both little cam and swing-arm wheel, the machine runs easily and stable.2) Rolling transmission is adopted in entire structure instead of slide block and slide rod, which doesn't need lubricant and decreases the wearing part.

3) With the detector for warp-breaking, welf-breaking and weft-ending, the sensibility for automatic stop becomes reliable.

4) It's an environmental product whose noise is not more than 82DB(A).

5) Low strength plastic yarn which is made from 100% regenerated plastic can be adopted to weave.

6)It is high-efficient and energy economical. The highest rotation speed of the main motor can reach 180/min and the power is 1.5/2.2kw, which can save 10 thousand degree of electricity one year compare with the old type circular loom which motor is 4KW.

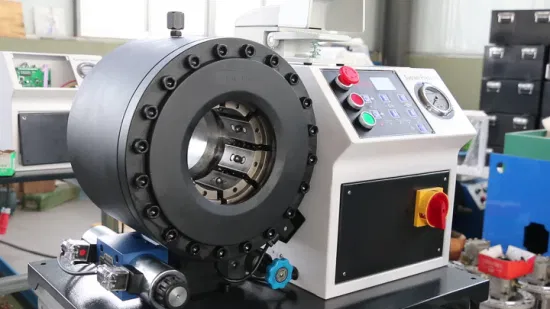

Detailed ImagesMain part of circular loom

Distribution box

Our Service

Pre-Sales Service .After-Sales Service

* Inquiry and consulting support. * Training how to instal the machine, training how to use the machine.

* View our Factory * Engineers available to service machinery overseas.

Our factory:

Our Contact