Plastic PE/PP/LDPE/LLDPE/BOPP/HDPE/Pet Bottle/Laminated/Film/Woven Bag/Non Woven Plastic Washing Recycling Machine

Description

Basic Info.

| Model NO. | PEW-300, PEW-500, PEW-1000, PEW-1500, PEW-2000 |

| Certification | ISO9001:2008, CE |

| Motors Brand | Siemens Brand |

| Electric Contactor | Siemens Brand |

| Drying Equipment | Centrifuge Dewatering, Pipe Dryer, Squeezer |

| Hot Washing | Included in Washing Recycling Machine |

| Related Products | Crusher, Shredder, Dryer |

| Next Step Machine | Plastic Extruder Pelletizing Line |

| Inverter | ABB Brand |

| Bearing Brand | NSK |

| Main Equipment | Plastic Crusher Shredder Washer, Dryer |

| Final Product | Clean and Dry Plastic Pieces |

| Washing Machine Material | Stainless Steel 304 |

| Cleaning Equipment | High Rotating Speed Friction Washer, Washer Tank |

| Water Consumption | 3-8 Ton/ Hr, Water Can Be Reused |

| Product Advantages | Shredder Low Speed, High Torque and Low Noise |

| Recycling Plastic Type | Waste PE, PP, HDPE, LLDPE, LDPE, Pet, PVC, PS, PA |

| Transport Package | Wooden Box |

| Specification | different model, machine size is different |

| Trademark | REGULUS |

| Origin | China |

| HS Code | 847780 |

| Production Capacity | 100sets/Year |

Product Description

Plastic Washing Recycling line

Product Description

What kind of plastic can be recycled?

The plastic film is a secondary resource with very good recycling value, and the recycled film can reproduce film products,plastic bags, injection products, wood plastic products, etc., and has a wide range of uses.The shape, size, moisture content, and impurity content of the waste film are not the same. The types of plastic films commonly found in therecycling market are:1. Production of post-consumer films (including collected from landfills and selectively collected)2. Commercial and post-industrial films (mainly in plastic bags and packaging films, stretch film)3. Agricultural film (including greenhouse, mulch, greenhouse film and banana film, etc.) Besides plastic film, the washing line can also recycle plastic jumbo bags, plastic bags, woven bags, non-woven, bottles, scraps, raffia, foil and other plastic.Mainly in Plastic PE, PP, LLDPE, HDPE, LDPE.

Zhangjiagang REGULUS Machinery Co., Ltd. is a group company. We devote ourselves to the development, research and production of

plastic machines, our main products include:Plastic PE PP PET PVC PS PA plastic crushing, washing, drying recycling line

Plastic PE PP PET PVC PS PA pelletizing/Granulating recycling line

Plastic shredder, Plastic crusher, Plastic agglomerator, Plastic mixer, Plastic pulverizer equipments

Plastic pipe extrusion production lines

PVC/ WPC profile extrusion line

Purpose and equipment composition

This production line is specially used for crushing, cleaning, dewatering and drying all kinds of waste plastics. The whole

production line is mainly composed of the following equipment: belt conveyor, crusher, friction cleaning machine, film rinsing machine, screw feeding machine, heat cleaning machine, screw feeder, dehydrator, drying system, electrical and so on. The equipment is simple, practical and high yield, which is the most effective production line for recycling waste plastics.

Product Parameters

| Model | Product Capacity | Motor Power | Equipment Footprint |

| Pew-300 | 300 kg/h | 100 kw | 120 m2 |

| Pew-500 | 500 kg/h | 150 kw | 200 m2 |

| Pew-1000 | 1000 kg/h | 190 kw | 310 m2 |

| Pew-1500 | 1500 kg/h | 250 kw | 500 m2 |

| Pew-2000 | 2000 kg/h | 290 kw | 600 m2 |

Larger, more powerful models available based on your request

Product Configuration

Main equipments of Plastic washing recycling lineThe entire plastic PE PP washing line is controlled via a central electric control panel and cabinet.

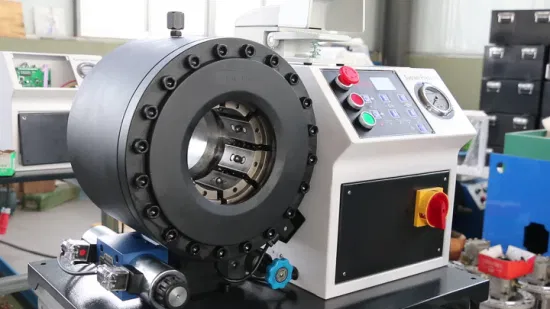

Plastic Shredder Machine :

The shredder is usallyequipped for large capacity washing line, and the shredder can shred whole film bales directly.Wet Plastic Granulator:

The plastic granulator cuts the plastic into smaller pieces. Crush with water which can clean the dirty waste plastic before moving onto the next washing machine.Friction Washer:

The friction washer is high rotating speed cleaning equipment. The plastic runs against each other at high speed geeting rid of hard to remove contamination.

Sink Float Separation Tank:

In the washing tank, the plastic PP and PE will float, and heavier contamination such as dirt , sand , glass ,metals , other plastics will sink .

Centrifugal Dewatering Machine:

The machine uses centrifugal force to remove a large portion of water within the plastic before moving forward onto the therma dryers.Screw Press Squeezing dryer:

Another kind of dewatering machine. the screw-press dewatering machine is a more advance version of the standard dewatering machine. The machine screw press squeezes the water out via high pressure.

REGULUS MACHINERY GROUPZhangjiagang Regulus Machinery CO.,LTD boasts teams of professional and high-efficient colleagues in technology, management, sales, and service. with our continuous efforts in technology development and product quality control, we have been adhere to the principle of putting customer's benefit at the first place by providing the most competitive technique in plastic industry within the shortest period of time to create a higher value for customer.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIMEREGULUS is professional manufacturer. Welcome you visit our factory. Regulus Machinery with own manufacture and developed & research team. In order to offer high efficiency after-sales service, our engineers are available to your factory for installation, commissioning, technical guidance and personnel training.

HOW TO ENSURE THE QUALITYIn order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years. Each component before assembly needs strict control by inspecting personnel. Each assembly is in charge by a master who has working experience for more than 15 years After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

SALES AND SERVICE NETWORK

COOPERATION BRAND

Packing and Delivery

Certifications

FAQ

Q1. Which kind of waste plastic can your machine recycle?

A1. Our company mainly produces plastic PE PP PET PVC PA EPS PS ABS recycling machine.

Q2:How can we know what kind recycling machine is suitable for our waste plastic?

A2:You could contact us and send us your waste plastic pictures, and tell us your requirement of product capacity. Wwe will recommend you suitable waste plastic recycling equipment.

Q3: How can we guarantee quality?

A3: All of our workers has more than 10 years experience in producing the plastic machine, and we always final Inspection before delivery.

Q4:. What kind of plastic machine can we buy from your company?

A4: Plastic Washing Recycling Line, Plastic Pelletizing Recycling Line, PET Bottle Recycling Line, Plastic pipe and plastic profile Extrusion Line, Plastic agglomerator, Plastic Squeezing dryer Machine, Plastic Shredder, crusher, plastic mixer, plastic pulverizer.

Q5: What services can your company provide?

A5: Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T, L/C

Please feel free to contact us for further details.

We are looking forward to forming a profitable business relationship with your company in the near future.

And Welcome to China, welcome you to visit our company at any time.

Our Contact